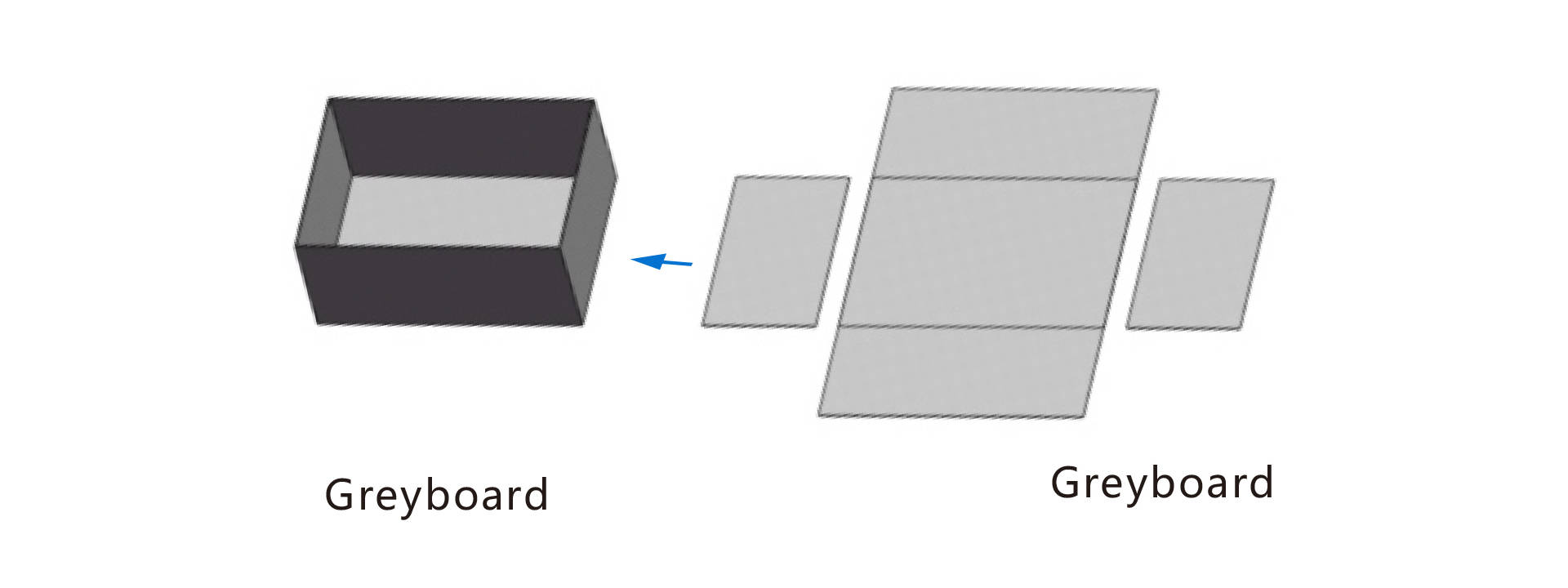

Greyboard assembling machine

Features and function

- Two side boards attaching to the triple board, greatly decrease the greyboard material loss

- The glue spray can output even glue between the attaches, without lacking glue or leacking glue

- Spot is highly accurate +/- 0.2mm

- Adopt PLC to control the machine, simple interface, easy operation, and each unit can be adjusted independently

Workflow

Technical parameters

| Model | HM-3525 | |

| Greyboard thickness | T min (mm) | 1.5 |

| T max (mm) | 5 | |

| Finished box size L = length, W = width, H = height | L min (mm) | 100 |

| L max (mm) | 350 | |

| W min (mm) | 60 | |

| W max (mm) | 250 | |

| H min (mm) | 20 | |

| H max (mm) | 180 | |

| Air supply (L/min) | 300 | |

| Air supply (MPa) | 0.8 | |

| Speed (pcs/min) | ≤ 25 | |

| Speed (pcs/h) | ≤ 1500 | |

| Total power (kW) | 7 | |

| Voltage AC (V) | 380 | |

| Power consumption (kW/h) | 2 | |

| Machine net weight (Kg) | 1200 | |

| Machine dimension (mm) | 2100 x 2300 x 2100 |